Affordability

Our relentless commitment to efficient machining keeps us ahead of the competition. Our manufacturing, engineering, and programming teams continuously seek innovative ways to enhance productivity. You’ll see the difference reflected in your quote.

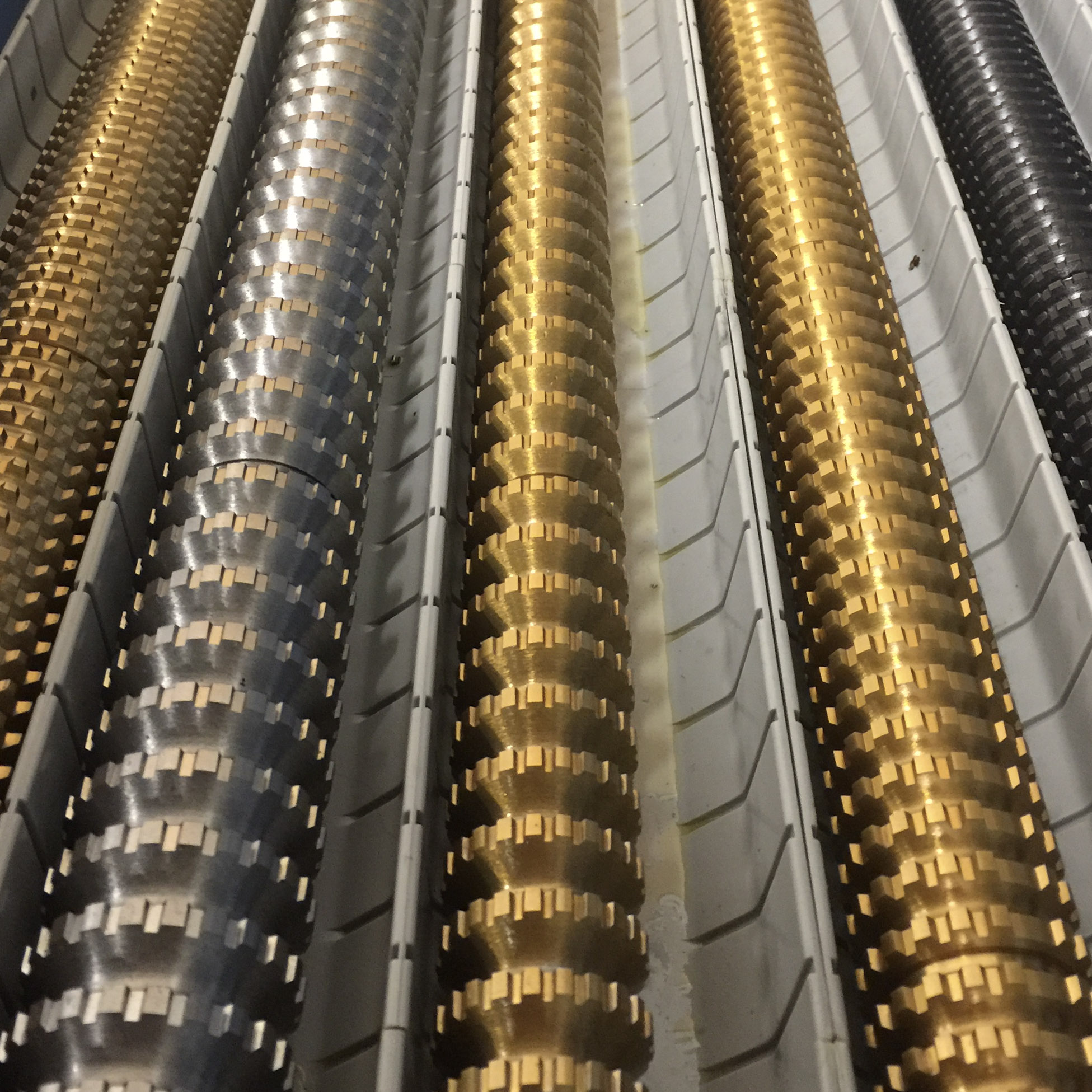

Material Capabilities

We specialize in hard metals and have extensive experience with a wide range of materials. Our expertise includes stainless steel, titanium, Inconel, aluminum, bronze, and brass.

Industries

Our contracts include aerospace, medical, dental, industrial, energy and automotive. If your product is not in one of these fields, we would still love to look at it!

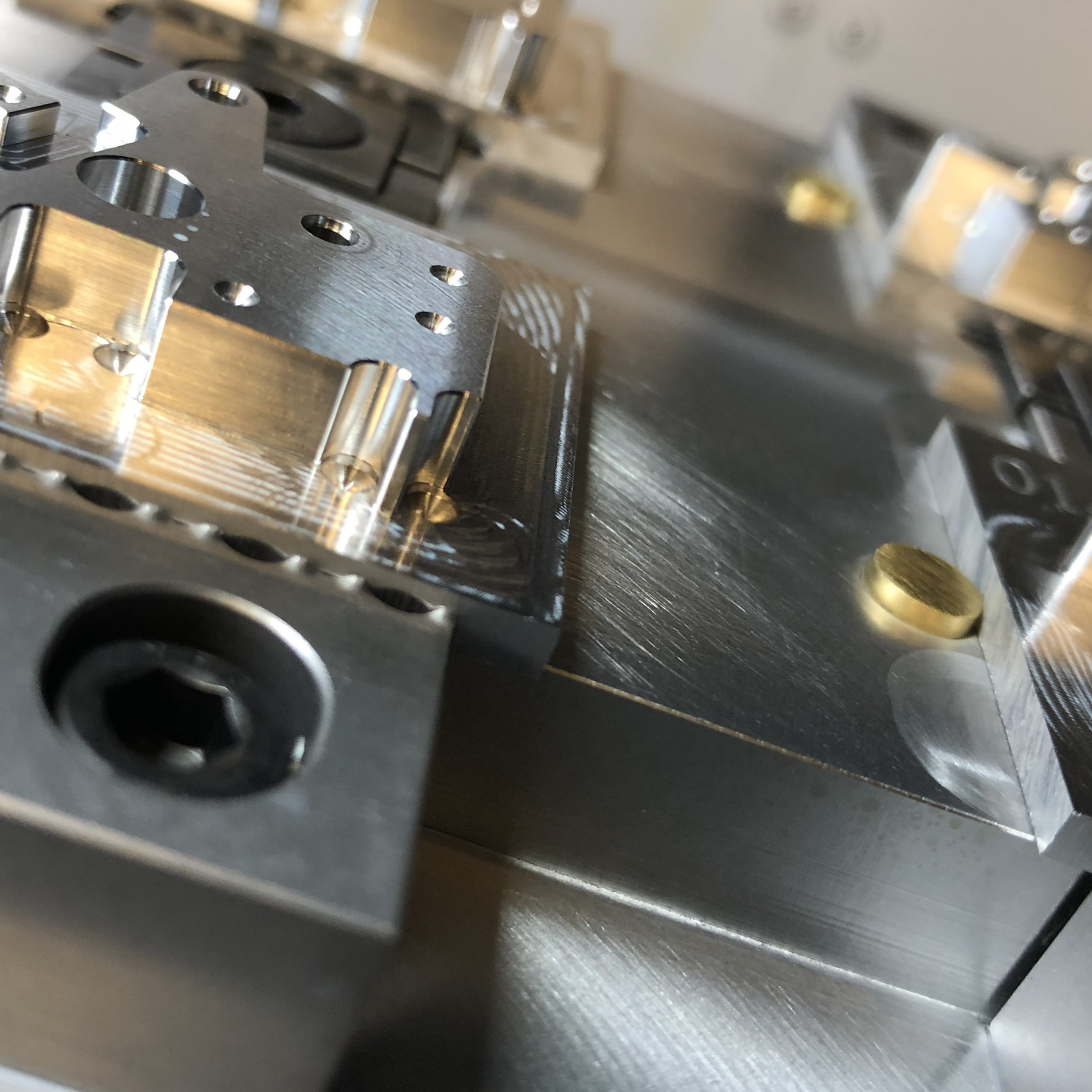

Precision

We specialize in precision machining and consistently work with tight tolerances, ensuring that every part we produce meets exact specifications with minimal deviation. This level of accuracy is essential for industries that demand high performance and reliability. Through advanced technology, skilled craftsmanship, and rigorous quality control, we guarantee that our parts meet the most stringent requirements.

Inspection

Our inspection capabilities are state-of-the-art. In addition to standard inspection equipment, we utilize a Mitutoyo automatic CMM, Starrett Vision system, and Micro-Vu video comparator. Our team is highly experienced in meeting FAI requirements, ensuring precision and quality in every part we produce.

Supply Chain Management

Material purchasing and all outside processes are carefully and accurately maintained by our supply chain team. All associated certifications will be passed along to you with delivery.

Team

Our team of expert journeyman machinists is dedicated to ensuring the highest quality for your products. We take pride in our exceptional quality ratings from customers—it's the reason they continue to trust us!

Software

We are able to accept all forms of 3D file formats for both quoting and manufacturing purposes. We employ Kubotek software for solid model verification before manufacture. We use Mastercam and Fusion for CNC programming.